Are you concerned with excessive scrap and production costs when working with high-value corrosion resistant alloys?

Corrosion Materials’ high-definition plasma cutting can produce squares, rectangles, strips, circles, rings and custom shapes, all while helping you minimize scrap, improve productivity and lower overall costs.

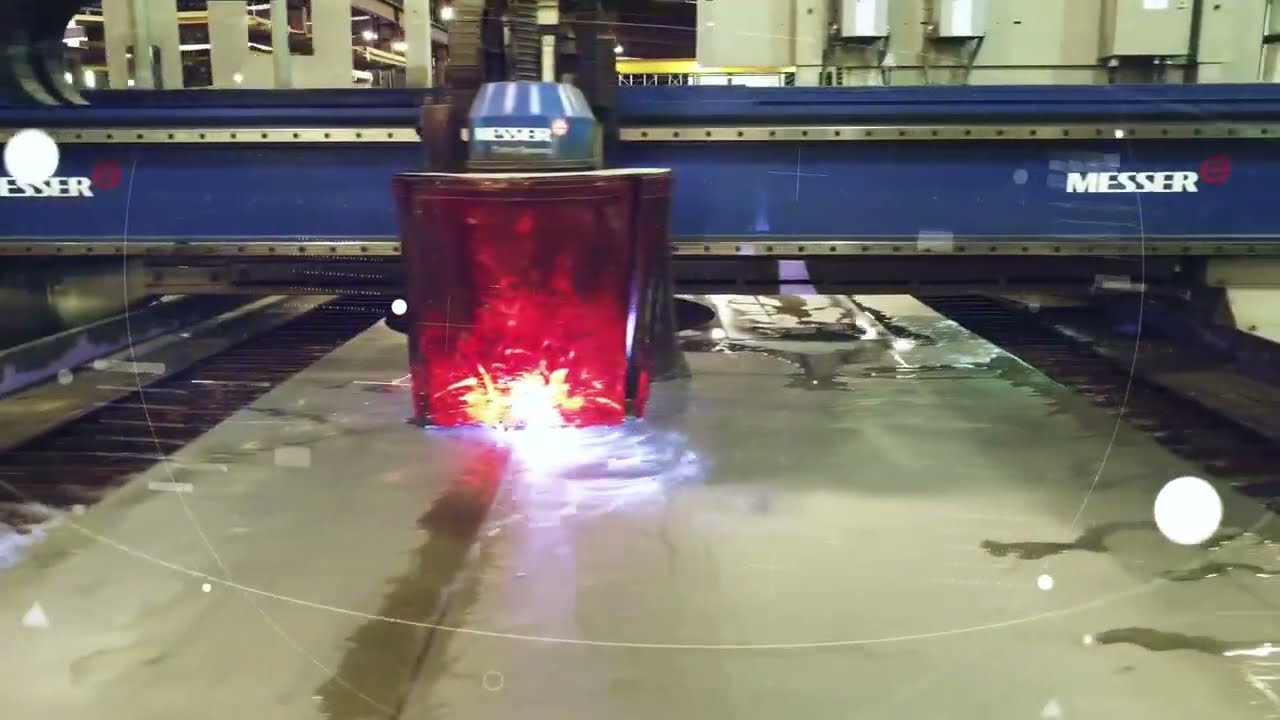

High-definition plasma cutting is a versatile cutting process in which the plasma arc is forced through a small nozzle to achieve clean, square cut edges. One of the most efficient and versatile machines for processing various thicknesses of materials with ease, high-definition plasma cutting delivers superior quality, productivity and operational efficiency for many types of components.

Standard or Custom Shapes

We specialize in processing squares, rectangles, strips, circles, rings and custom shapes. We can also bevel plate edges for weld preparation to V, K, X and Y bevels, saving you time and materials. Let us process your standard or custom shapes with our state-of-the-art high-definition plasma cutting and beveling equipment. We work with clients in many industries around the world to fill their orders with the high standards they have come to expect from Corrosion Materials.

Contact one of our experienced team members to help find what you’re looking for in our extensive inventory of corrosion resistant alloy products and value-added capabilities.