Nickel-Copper Alloys

Nickel-Copper (NiCu) alloys are an important sub-group of Nickel alloys frequently used throughout several industries and in various environments, such as those containing reducing acids, alkalis, or seawater. In fact, Nickel-Copper alloys are commonly used in marine applications because of their low macrofouling rates and excellent resistance to seawater corrosion.

Alloy 400 (Monel®)*

The most well-known NiCu alloy, Alloy 400 (N04400), is considered to be one of the first, nickel-based corrosion resistant alloys. Alloy 400 has high strength and toughness over a wide range of temperatures and offers very good resistance to many corrosive environments. Alloy 400 is frequently used in the marine and chemical process industries. Typical applications include pumps, valves, mechanical seals, propeller shafts, marine fixtures, electronic components, springs, chemical processing tanks, process vessels and piping.

Alloy 405 (Monel®)*

Alloy 405 (N04405) is a variant of alloy 400 that has an increased sulfur content to enhance machinability. This alloy maintains the strength and corrosion resistance of traditional alloy 400 and exhibits similar corrosion resistance properties. This alloy is resistant to corrosion in many reducing media. Like alloy 400, alloy 405 is one of the few alloys that can be used in contact with fluorine, hydrofluoric acid, hydrogen fluoride, or their derivatives. Exceptional corrosion resistance has been proven in hydrofluoric acid in all concentrations up to the boiling point. Alloy 405 is also resistant to many forms of sulfuric and hydrochloric acids under reducing conditions. Corrosion resistance behavior in seawater is outstanding. Typical applications included fittings and fasteners for the marine and chemical process industries.

Alloy K500 (Monel®)*

Alloy K500 (N05500) is considered the high-strength NiCu alloy. The additions of aluminum and titanium to the nickel-copper base allow for subsequent heat treatment that increases the mechanical properties. Alloy K500 also has low magnetic permeability and strong non-magnetic characteristics, with some specifications requiring a less than 1.01 magnetic permeability, over a wide range of temperatures, including subzero. It also has the excellent corrosion resistance of alloy 400 but with improved strength and hardness, and can be used in other applications where alloy 400 is limited. Alloy K500 is frequently used in the marine, chemical processing, oil and gas, pulp and paper, pharmaceutical, food processing, and electronic industries. End-use applications for alloy K500 include fasteners, springs, chains, pump and valve components, drill collars, doctor blades, scrapers, mixing shafts, impellers, sensors, electrical components, and other highly corrosive applications where strength and hardness are important. This alloy can be supplied in the annealed, annealed and aged, or direct-aged conditions.

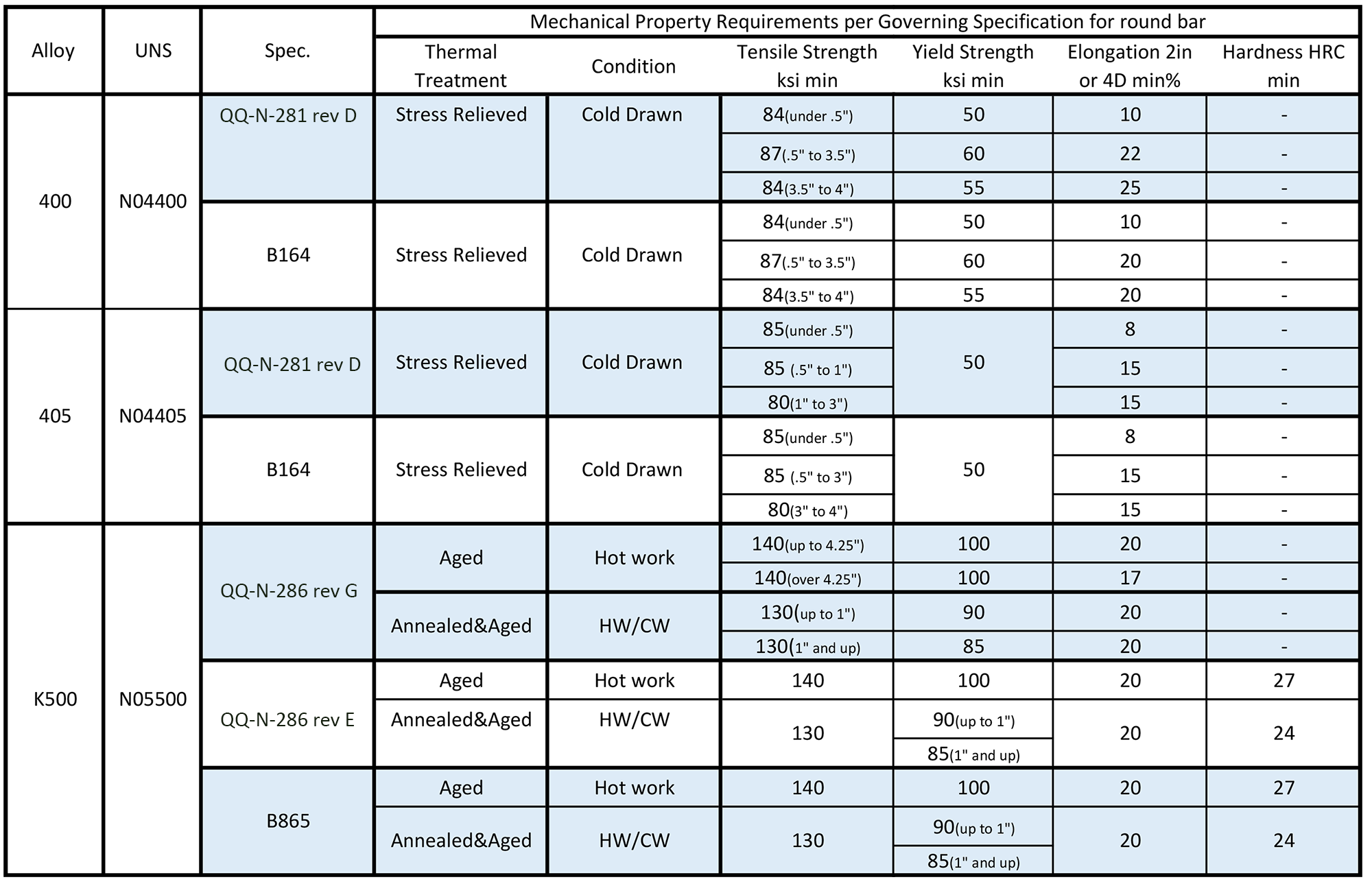

Mechanical Properties

MORE INFORMATION

Download full data sheets of each alloy or request a quote for your specific requirements. Our industry experts are always available to answer all your questions about how we can help you with your alloy needs.

Sources:

- A Century of Monel Metal: 1906-2006, by Lewis E. Shoemaker & Gaylord D. Smith, Huntington Alloys/Special Metals Corporation Huntington WV

- History of Monel Alloy K500, by E.L. Hibner and Dr. T.F. Lemke, 2011

- Special Metals Corporation Alloy 400, R405, and K500 datasheets.

* Monel® is a registered trademark of Special Metals Corporation, a PCC Company.