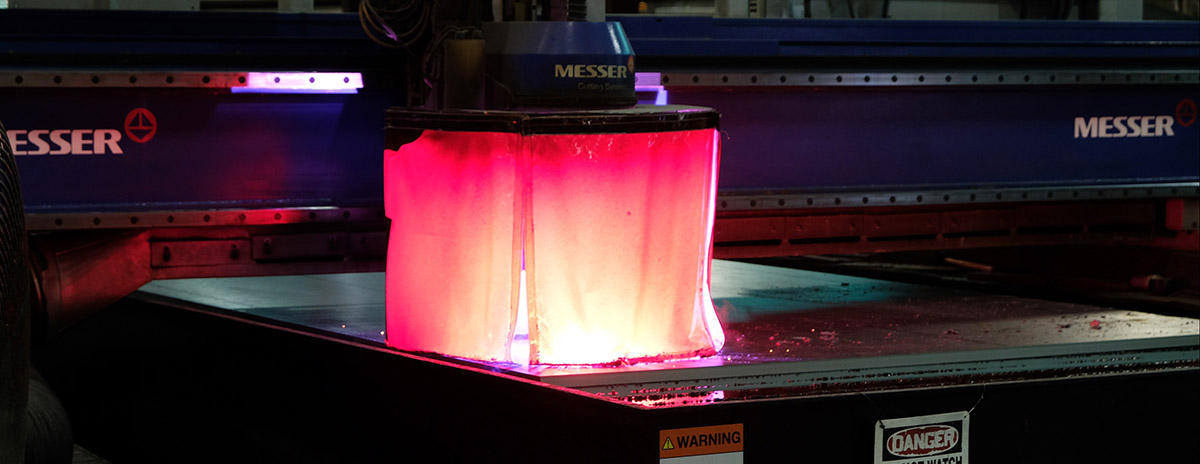

Plasma cutting is a process used to cut conductive materials such as nickel alloys, carbon steel, stainless, aluminum, brass, or copper using a plasma torch. The plasma cutter is one of the most efficient and versatile machines for processing various thicknesses of materials with ease, making it an ideal cutting choice for many types of components.

Advantages of Plasma Cutting

CNC high-definition plasma cutting has significant advantages over alternative cutting methods. Some of its benefits include:

Speed

A plasma cutting machine can cut material faster than other cutting processes, such as oxy or waterjet. Because the plasma can quickly achieve high temperatures, this allows plasma cutters to slice through materials faster than many other cutting techniques. Increasing the rate of production helps reduce overall cost.

Efficiency

The speed at which a plasma cutter can process material makes it an incredibly efficient cutting process. Modern CNC technology also allows for better automation, which results in enhanced productivity, consistency, and repeatability.

Versatility

Versatility

One of the key advantages of plasma cutting is its versatility. The plasma cutting machine has the ability to make precise cuts on various types of materials over a wide range of thicknesses and widths.

High Quality

A high-definition plasma cutting machine forces the plasma stream through a small nozzle, concentrating more energy in a smaller area and increasing plasma density. This results in more precise cuts than many other cutting methods. With an experienced operator, the plasma machine can produce consistent edges with minimal kerf.

Cost Efficiency

Compared to other cutting techniques such as laser or waterjet, plasma cutting is a more cost-effective process. Not only is it fast and efficient, but it also leaves behind little scrap, which makes it an economical choice.

Are you concerned with excessive scrap and production costs when working with high-value corrosion resistant alloys?

Corrosion Materials’ high-definition CNC plasma equipment can help you reduce scrap, improve productivity and lower overall total cost.

Corrosion Materials’ high-definition CNC plasma equipment can help you reduce scrap, improve productivity and lower overall total cost.

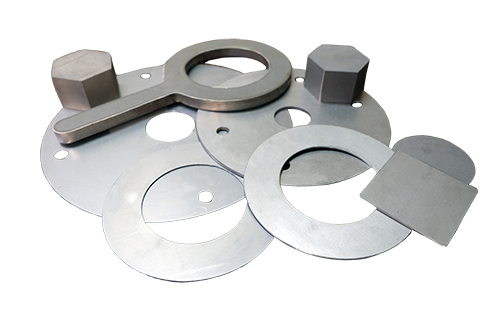

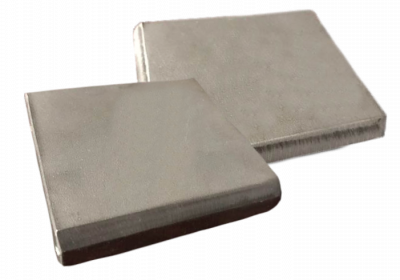

We specialize in processing squares, rectangles, strips, circles, rings and custom shapes. We can also bevel plate edges for weld preparation to V, K, X and Y bevels, saving you time and materials. Let us process your standard or custom shapes with our state-of-the-art high-definition plasma cutting and beveling equipment. We work with clients in many industries around the world to fill their orders with the high standards they have come to expect from Corrosion Materials.

Contact one of our experienced team members to help find what you’re looking for in our extensive inventory of corrosion resistant alloy products and value-added services.