“Connecting” to the Value Chain

Many in the manufacturing world are constantly concerned with keeping up with what will be the next new thing in equipment. Large companies can experiment with new pieces, but for many small and mid-sized companies, new equipment needs to be a solid investment. With constant changes in technology, what should we be focusing on when it comes to deciding when to upgrade and how long to stick with existing pieces of equipment? How much value should be placed on smart, “connected” machines?

One of the most valuable things to many manufacturers is fewer disruptions for maintenance issues on the floor. Machines that can manage themselves by adjusting temperature, sending alerts, and even be repaired remotely, vastly increase the effectiveness of the manpower on the shop room floor.

In standard products, it costs a lot to change between models. But with smart products, variation is more cost effective. John Deere historically manufactured multiple versions of engines, each providing a different level of horsepower. It can now alter the horsepower of a standard physical engine using software alone. ¹

Large machine parts used to be evaluated with tests that tried to mimic the conditions under which it would be used in on the factory floor. Connected machines can be sent software updates that will manage the quality of the machine as it and others like it message conditions and usage issues faced in the factory itself. When the service histories, product use, environmental variables, and performance from many machines that transmit their own data are combined, companies can adjust accordingly. Service can be customized and preempt an expensive repair.

In 2013, batteries in two Tesla Model S cars were punctured and caught fire after drivers struck metal objects in the road. The road conditions and speeds leading to the punctures had not been simulated in testing but Tesla was able to reconstruct them. The company then sent a software update to all vehicles that would raise their suspension under those conditions, significantly reducing the chances of further punctures.²

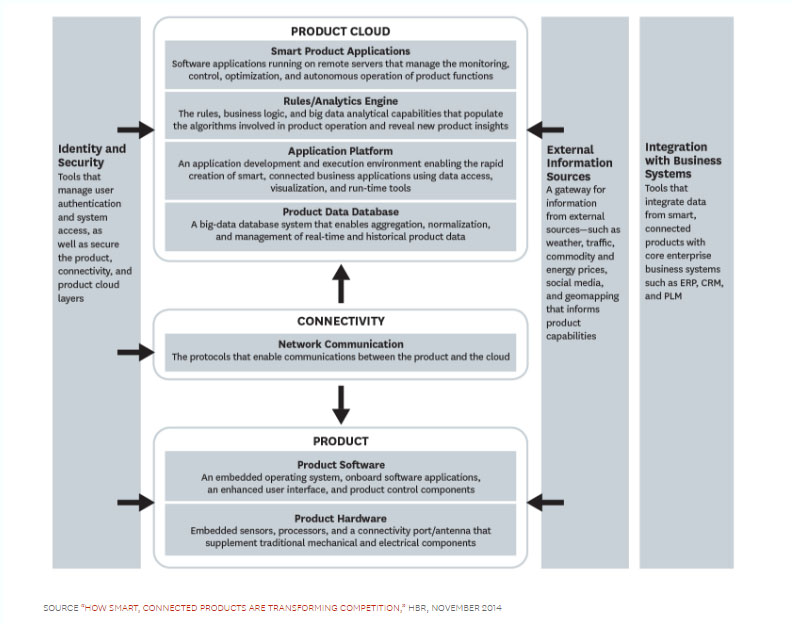

Collecting these figures is the role of data analytics programs. They require a combination of physical, smart and connectivity components. A “technology stack” like this can be thought of like a platform for you collect, store, and analyze your data by running applications that break down the data into what is useful in your company.

Gateways ∼

Linking existing legacy devices to the IoT is major to OEMs. The software that connects devices to a point in the cloud to turn the data coming from the floor into useful information is called a “gateway.” Right now, 85% of all devices are not connected to any sort of cloud, therefore not submitting data for analytics or remote management. There are several companies offering valuable gateway devices that allow manufacturers to pull the data they need from previously unconnected devices to operate more efficiently.

Before implementing new data collection systems ∼

Determine what information will be valuable to your company and clearly communicate the data that will be most relevant to collect. Remember you can’t understand what you cannot measure. At smaller manufacturers and job shops, there is a growing desire to monitor the shop floor, understand part flows, planned versus actual performance, run programs, and access paperless information. ³

Make sure all staff – including management- are trained prior to making any changes to manufacturing floor routines. Set up one-on-one training sessions with staff that will leave everyone comfortable with using the system.

Most manufacturing companies can find data collected from new or legacy devices will provide them with better support for their customers and give them the tools they need to fix any weaknesses in their part of the chain. Integrating data collection devices on your manufacturing floor can completely transform how you create value for your customers.

References:

1, 2Michael E. Porter, J. E. (n.d.). Harvard Business Review. Retrieved from https://hbr.org/2015/10/how-smart-connected-products-are-transforming-companies

3 Waurzyniak, P. (2015, October 1). sme.org. Retrieved from http://www.sme.org/MEMagazine/Article.aspx?id=8589936436