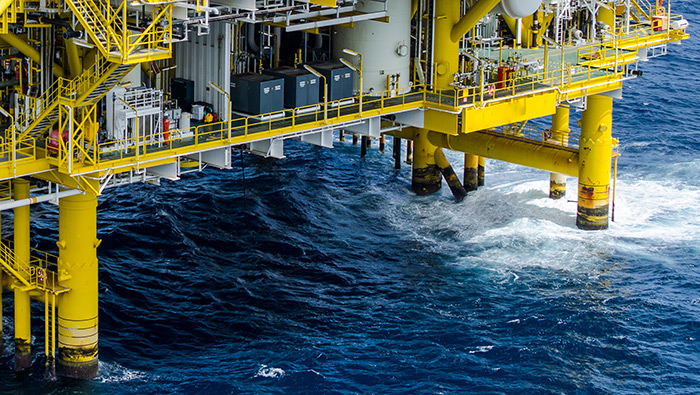

“The conditions under which oil and gas are brought from their reservoirs to the surface can be outright hostile to many common materials used in fluid system components employed in the industry.”

According to Dr. Gerhard Schiroky, potentially dangerous mechanisms including localized corrosion, stress corrosion cracking (SCC), and sulfide stress cracking (SSC) have become increasingly dominant as more sour reservoirs are being developed. He describes how to select the optimal materials of construction for components that need to perform reliably for many years in the demanding sour environments of oil and gas exploration and production.

Pitting Corrosion (or Crevice Corrosion) happens when the passive oxide film on an alloy surface breaks down in a chloride-rich environment. The higher chloride concentrations, more acidic environments, and elevated temperatures, the more likely there will be a breakdown of this passive film. The higher an alloy’s Pitting Resistance Equivalent Number (PREN), the higher its resistance to localized corrosion. This is calculated as PREN = %Cr + 3.3(%Mo + 0.5%W) + 16%N.

Stress Corrosion Cracking (SCC) – Certain alloys are susceptible to SCC. SCC occurs when chloride ions interact with the material where tensile stresses are highest. This produces stress levels that are below the yield strength of an alloy and failure can occur. Nickel base alloys are highly resistant to SCC.

Sulfide Stress Cracking (SSC) – For SSC to occur there must be a susceptible material, a fluid with H2S concentrations above a threshold, and a tensile stress above a critical level. When a susceptible metal surface comes in to contact with sour gas, the H2S molecules react to form metal sulfide and hydrogen atoms.

“Petroleum and natural gas industries –Materials for use in H2S-containing environments in oil and gas production” (ISO 15156) addresses all mechanisms of cracking that can be caused by H2S, including SSC and SCC, and other forms of hydrogen-induced cracking.

Solid Solution Nickel-Based Alloys – ISO 15156 defines five material types for solid-solution nickel-based alloys based on its solution annealed or cold-worked.

“Commonly used alloys… Alloy 625 and Alloy C-276 can be used in the solution-annealed or annealed condition for any equipment or component at any combination of temperature, H2S partial pressure, chloride concentration, and in situ pH occurring in production environments.

For downhole tubular components, cold-worked alloys … Alloy 625 and Alloy C-276 can be used if their hardness does not exceed 40 HRC and their yield strength is not above specific limits. Alloy C-276 can be used at higher temperatures and H2S partial pressures than Alloy 625…”

According to Dr. Schiroky, “When a customer orders a specific valve, fitting, or other fluid system component for sour gas service, the manufacturer should perform a product review in which all wetted parts are evaluated against standard requirements, e.g., for type of material, manufacturing processes, and maximum hardness. Such a review ensures the products selected for sour gas service meet ISO 15156 requirements, as well as the customer’s requirement for durability, excellent performance, and reliable service.”

At Corrosion Materials, we have a wide range of Alloy 625 and Alloy C-276 products in our inventory and the in-house capabilities to customize our stock to your needs. Speak to one of our industry experts for more information on how we can help you with all your alloy needs.